Posted on 5/12/2025

BMW N55 Engine Warning: How a Simple Belt Failure Can Destroy Your Engine The BMW N55 engine, found in numerous models such as the 335i, 435i, and various X and M-performance series vehicles, is renowned for its performance and smooth turbocharged power delivery. However, it harbors a critical design flaw that can lead to catastrophic engine failure At the heart of this issue lies the serpentine drive belt system. This belt runs multiple accessories such as the alternator, power steering pump, and air conditioning compressor. In the N55, the drive belt rides on a crankshaft pulley (also called the harmonic balancer) at the front of the engine. Under normal conditions, this setup works reliably. But when oil contaminates the belt, a dangerous cascade of events can unfold. The Root Cause: Leaky Oil Filter Housing Gasket The most common culprit for belt contamination is a leaking oil filter housing gasket (OFHG). Positioned directly above ... read more

Posted on 4/14/2025

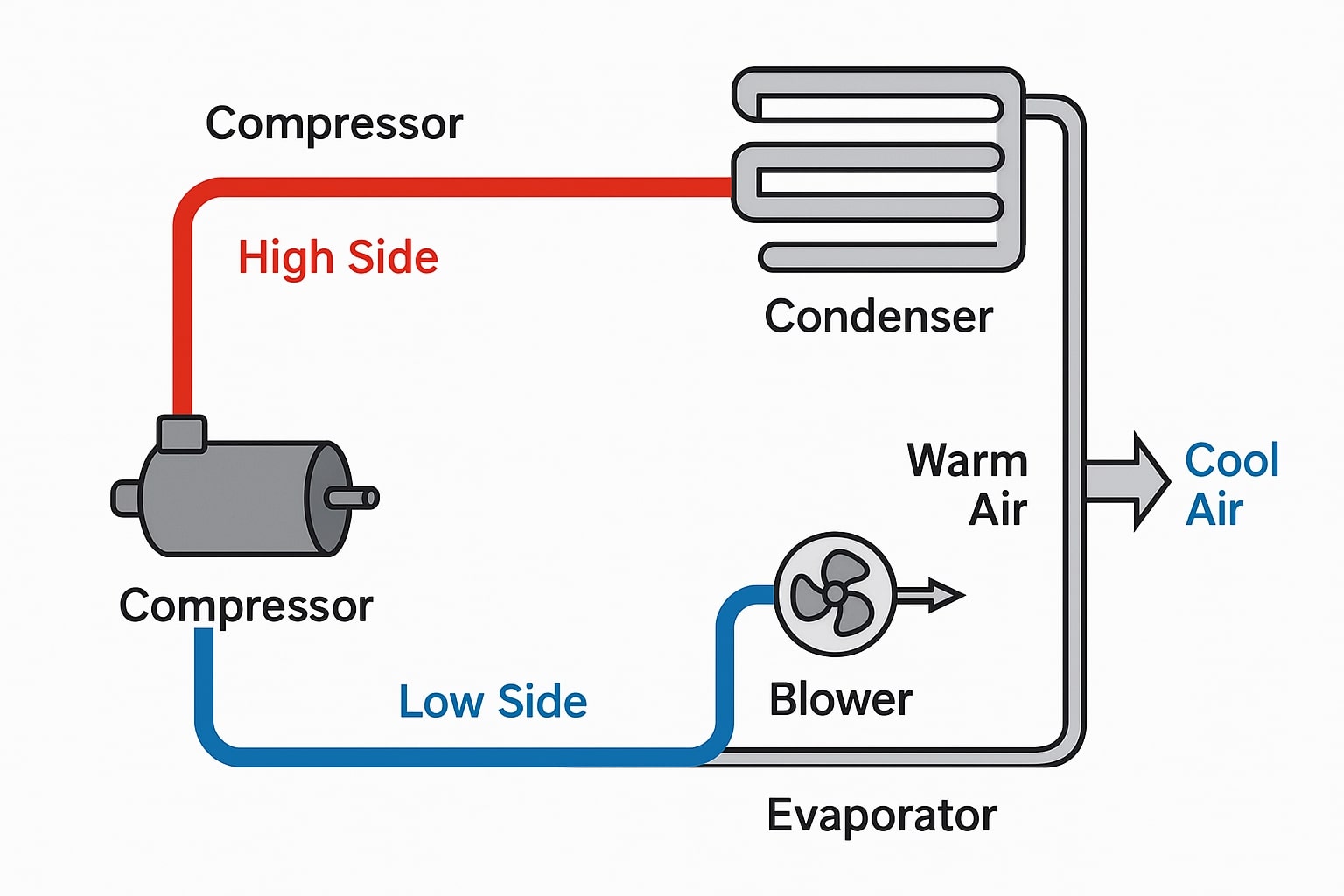

Whether you're driving a sporty BMW 3 Series, a luxury Mercedes-Benz E-Class, or a rugged Land Rover Discovery, having a fully functioning air conditioning (A/C) system is essential—especially when the temperature rises. But have you ever wondered how your car A/C actually keeps things cool? Let’s break it down in simple terms. Why Does a Can of Compressed Air Get Cold? If you’ve ever used a can of compressed air to clean your keyboard or electronics, you may have noticed that the can gets very cold after a few seconds of use. That’s no accident—it’s basic thermodynamics in action. When the compressed gas is released, it expands rapidly. As it expands, it absorbs heat from its surroundings, It is this heat absorption which causes the cooling effect. Your car's air conditioning system works in m ... read more

Posted on 4/8/2025

Seized Lug Nuts: A Hidden Danger for BMW and Audi and Volkswagen Owners When it comes to vehicle maintenance, tightening lug nuts may seem like a small detail—but for BMW and Audi/ VW drivers, overlooking proper lug nut care can lead to major issues. One of the most common and frustrating problems is seized lug nuts. This issue not only makes basic repairs like tire changes nearly impossible but can also lead to dangerous roadside emergencies. What Causes Lug Nuts to Seize? Lug nuts become seized primarily due to over-tightening, often done using an impact wrench without a torque limiter. This excessive torque can stretch or damage the threads, leading to the lug nut fusing with the wheel stud. Over time, exposure to moisture, road salt, and heat cycles further exacerbates the problem, especially if no anti-seize lubricant is used during installation. BMW,Audi and Volkswagen models, known for their precision engineering, are pa ... read more

Posted on 3/30/2025

Understanding the BMW Eccentric Shaft Sensor/Actuator BMW’s Valvetronic system is a key component of its efficient and high-performance engines, offering precise control over valve lift for improved fuel efficiency and performance. Central to this system is the eccentric shaft, eccentric shaft position sensors, and actuators. These components work together to fine-tune the engine’s airflow and enhance responsiveness. Role of the Eccentric Shaft, Sensor/Actuators The eccentric shaft in BMW engines adjusts the angle of the intake valves, allowing for variable valve lift. This eliminates the need for a traditional throttle body, reducing fuel consumption. The eccentric shaft position sensor monitors the position of the shaft and sends data to the engine control module (ECM), ensuring accurate adjustments. The actuator, on the other hand, receives commands from the ECM to rotate the eccentric shaft. In short, it saves you on gas money through increased engine efficienc ... read more

Posted on 3/24/2025

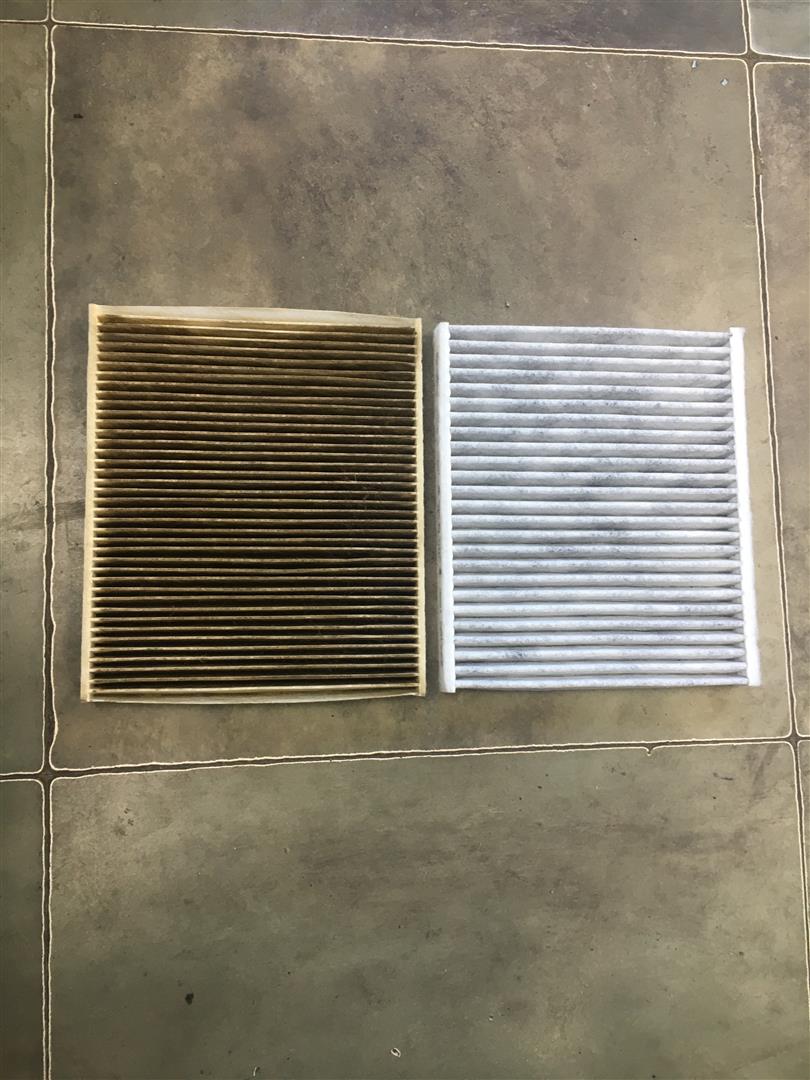

The Importance of Changing Your Cabin Air Filter Every Year Most drivers know the importance of changing their engine oil and air filter, but one often-overlooked component is the cabin air filter. This small but crucial part plays a significant role in maintaining air quality inside your vehicle. Replacing your cabin air filter annually can improve air quality, reduce health risks, and enhance the overall driving experience. What Does a Cabin Air Filter Do? Whenever you turn on your A/C or heat, the vehicle is pulling air from the outside of the car, passing it through a filter and blowing it into the cabin. The filter it is passing through is called a cabin filter. It is responsible for purifying the air that enters your vehicle’s interior through the heating, ventilation, and air conditioning (HVAC) system. It traps dust, pollen, bacteria, exhaust fumes, and other pollutants, preventing them from circulating inside your car. By doing so, it ensu ... read more

Posted on 3/16/2025

Rodent Damage in Luxury Cars: A Common Issue in NYC and Brooklyn Car ownership in New York City, especially in areas like Brooklyn, means dealing with all sorts of urban challenges, one of which is rodent infestations. Owners of luxury vehicles such as BMW, Audi, Volkswagen, Mini Cooper, Land Rover, and Mercedes-Benz are increasingly dealing with costly rodent damage when rats or mice find their way into your car's engine compartment. Why Are Rodents Attracted to Your Car? Rodents seek shelter in warm, dark, and enclosed spaces to escape predators and harsh weather. Your car’s engine compartment provides the perfect hiding spot, especially during cold New York winters when the warmth of a recently driven car becomes an inviting refuge. Additionally, the clean and relatively undisturbed space under the hood is ideal for building nests, making it an attractive haven for rats and mice. This is an acute problem for vehicles that have been parked for a lo ... read more

Posted on 3/9/2025

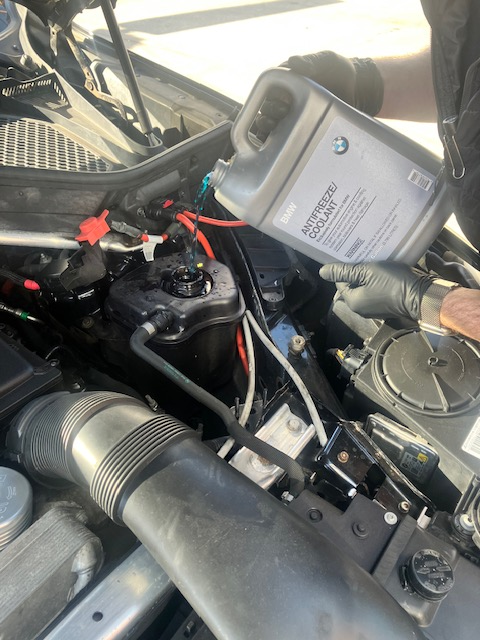

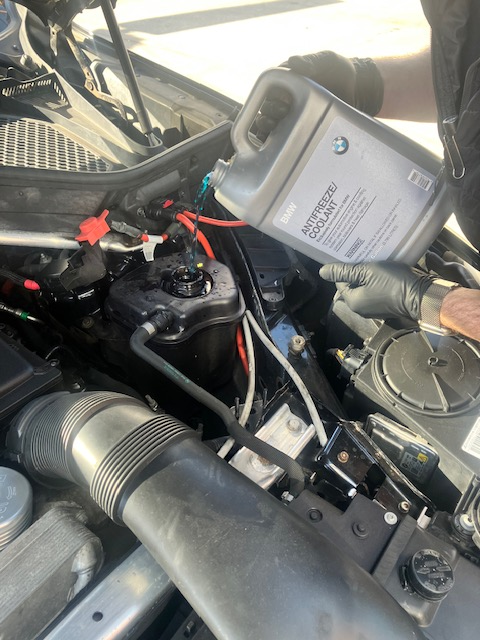

The Ultimate Guide to Coolants for BMW, VW, Audi, Mini Cooper, and Mercedes What Is Coolant and Why Is It Important? Coolant, also known as antifreeze, is a crucial fluid in your vehicle's engine cooling system. It prevents overheating in summer and freezing in winter while protecting engine components from corrosion. Over time, coolant degrades, leading to sediment buildup that can clog your radiator, water pump, and heater core, potentially causing severe engine damage. Types of Coolants by Color and Brand Different car manufacturers use specific coolant formulations designed to work with their engines and materials. Using the correct coolant for your vehicle ensures optimal performance and longevity. Here’s a breakdown of common coolant colors and their applications: Blue Coolant Used by BMW, Mercedes-Benz, Mini Cooper, and some Volkswagen models. Formulated with organic additives to provide long-lasting corrosion protection. Typically comes as a c ... read more

Posted on 3/9/2025

Owning a BMW comes with the responsibility of maintaining its high-performance engine. BMWs are precision-engineered machines, but like any car, they require regular care to keep running smoothly for years to come. Whether you own a classic 3 Series or a modern X5, following these expert maintenance tips will help extend the life of your BMW’s engine and avoid costly repairs. 1. Stick to Regular Oil Changes Oil is the lifeblood of your engine, keeping moving parts lubricated and reducing wear and tear. BMWs typically require high-quality synthetic oil, and ignoring oil changes can lead to sludge buildup, poor performance, and even engine failure. We recommend changing the oil in your BMW at regualr intervals, typically every 5,000 miles or once a year(whichever comes first) and use Liqui ... read more

Posted on 3/4/2025

Understanding Frozen Brake Calipers in BMW and Land Rovers: Causes and Consequences Brake systems in vehicles are designed to provide smooth, reliable stopping power, but they are also subject to wear and tear over time. One issue that can arise, particularly in BMWs and Land Rovers, is frozen brake calipers. This can lead to several problems, including excessive brake pad wear, rotor warping, and discoloration of the rims due to brake dust. Understanding how the brake system works and how a caliper can seize is essential for maintaining your vehicle's performance and safety. How Brakes Work The brake pedal is connected to a master cylinder, which holds brake fluid under pressure. When the driver presses the brake pedal, it forces the brake fluid through the brake lines, causing hydraulic pressure to build. The brake caliper is a crucial component in the braking system. It surrounds the brake rotor, which is a large metal disc attached to the wheel. The caliper contains ... read more

Posted on 3/2/2025

The Importance of Pre-Purchase Inspections for BMW, Audi, Mini Cooper, Land Rover, and Mercedes Purchasing a luxury car is an exciting experience, but it also involves a significant investment. Whether you’re eyeing a sleek BMW, a high-performance Audi, a stylish Mini Cooper, an adventurous Land Rover, or a prestigious Mercedes-Benz, it’s essential to protect your investment with a pre-purchase inspection (PPI). A PPI helps ensure you’re not only getting a great deal but also avoiding hidden issues that could lead to costly repairs down the road. The simplest way to get a pre-purchase inspection done is to find a trusted local shop located close to the vehicle you’re look ... read more